About us

History

The first form of association of cement producers in this area started with the Cement Cartel of the Kingdom of Yugoslavia, established during the middle of the Thirties of last century, headquartered in Belgrade.

After the Second World War, the domestic cement industry was initially organized first within the framework of the Federal Directorate for the Construction Materials Industry, later passing under the jurisdiction of the Federal Construction Chamber, whose headquarters was established, according to the then prevailing distribution of locations, in Zagreb, at the end of the Forties.

With the dissolution of that Chamber, an initiative was floated to establish a Yugoslav Association of Producers of Cement and Asbestos Cement. The idea required some time to mature, resulting in the fact that JUCEMA as a separate and independent legal entity was formed in 1956 (although some still maintain that it was done in 1953). The headquarters of JUCEMA (the Business Association of Yugoslav Cement Producers and Producers of Asbestos Cement) remained in Zagreb.

JUCEMA was divided into 3 sectors: general affairs, economic and research. The main purpose of association was the development of technology and capacities, common pricing policy, the securing of quotas of imported fuels and intermediary products, settling of import quotas and distribution of imported cement, cooperation with similar associations in foreign countries and with scientific research institutions, collation and exchange of data, publication of professional magazines and similar related activities. By decision of all its members (14 producers at 16 different locations) and as a result of the at that time adopted law whereby association was allowed only through and within Chambers, JUCEMA was abolished and disbanded in 1989/1990. The tradition of association was resumed by cement producers in 1997, through the establishment of the Business Association of the Cement Industry of Serbia (CIS), adjunct to the Ministry for Industry of the Government of Yugoslavia, as a quasi – state organ.

After the privatization of the cement industry in 2002, the association was conceptually reorganized as an organization based on the principle of voluntary membership and with the full respect of and compliance with rules and regulations governing protection of competition. In the aim of further compliance with the laws of the Republic of Serbia, in the period from 2010 - 2012, relevant amendments of general documents were performed and the Business Association Cement industry of Serbia was established.

The establishment and development of cement industry in Serbia

How it all began…

The first available data goes back to 1839, the time when marl from Beočin was used for the construction of the chain bridge linking Buda and Pest. There is no data that could reveal who first found marl at Beočin, but the assumption is that it was Adam Clark, the builder of that same bridge. As it were, the historian Futo Mihaly notes that in 1855 a miller from Apatin, Joseph Cik for the sum of 100 forints purchased the Beočin quarry from a Beočin-based company, “Weiner Waser Baumto” and this year is thus taken as the official date of the start of production at Beočin.

Not long after, in 1860, a man with vision arrives to Beočin – Hinrich Ohrenstein, who rents from Beočin monastery 20 acres of land and starts his own production, as a competitor to Cik. The competition between the two rivals will last until their Cik’s death.

Both cement plants at that time manufactured the so-called “Roman” cement, but Cik’s business spirit soon resulted in significant changes. After his visit to the World Fair in Paris in 1867, desiring to learn the “secret” of recipe for the recently discovered Portland cement, Cik finds clandestine employment in a British cement plant and even manages to become a construction engineer at the Polytechnic Academy in Vienna. Returning to Beocin, Cik modernized his own plant.

Thanks to their acumen and business spirit, after Cik’s death Ohrenstein and his partners, Spietzer and Redlich purchased Cik’s plant at an auction in 1898. The new company will bear the name “Union of Beočin Cement Plants Redlich, Ohrenstein and Spietzer”.

Thanks to their acumen and business spirit, after Cik’s death Ohrenstein and his partners, Spietzer and Redlich purchased Cik’s plant at an auction in 1898. The new company will bear the name “Union of Beočin Cement Plants Redlich, Ohrenstein and Spietzer”.

On the other side of the Danube, deep in Middle Pomoravlje, the valley of the Morava River, in 1869 Nikodije Pavićević came to the idea to first bake and then grind in a mill baked gray earth, resulting in the obtaining of cement. Soon afterwards that same year, Belgrade businessman Lazar Popovic in Popovac establishes a plant: in a shaft kiln of two meters circumference and using a mill on the riverbank he baked clinker and milled cement.

The first half of the twentieth century

By 1903, the Popovac cement plant was already producing 700 tons of cement annually and had found its place on the Serbian market, with plans for exports as well. The competitiveness of the new, industrially manufactured construction material did not pass the attention of the Belgrade Commercial Bank which became the owner of the plant and started with large-scale investment. With two vertical kilns and new mills, powered by steam turbines of 450 HpW, production levels were raised to 25 tons of “Roman” and “Portland” cement daily.

In 1904 a habitation colony is established at Beočin and production is modernized further. Expanding its business area, the stock company owning the cement plant purchases two more installations, one in Slovakia and one in Hungary, as well as another mine. In 1910 a funicular is installed linking the plant and the “Erdelj” quarry. That same year, the plant’s production capacity rose to 600 tons of Portland clinker in 24 hours in 20 kilns and 150 tons of Roman clinker in 6 kilns. The capacity of the “Filijala” plant was 200 tons of Portland cement in 6 kilns and 50 tons of Roman clinker in 2 kilns each 24 hours.

Just before the First World War, the Popovac plant changes owners once again : the mine at Sisevac and the plant itself become ownership of the newly established “French-Serbian Cement Industry a.d.” The capital, mainly of French and Czech origin, is set to the amount of 3.300.000 dinars, that is, 3.300 shares of a nominal value of 1.000 gold dinars. The new owners in 1913 install the first rotation kiln and increase production levels to 60 tons per day or 20.000 tons of cement annually. For the purposes of transportation of cement a small-gauge railway track is built to Paraćin, while raw material from Sisevac is hauled by use of a new funicular.

After the end of the First World War and nationalization in 1919, the Beočin plant continues to expand. The financial crisis in the country in 1925 influences cement production as well, but already in 1926 Beočin introduces a “special cement” that receives high recognition. The plant is further modernized in 1930, with the construction of a clinker hall and a large milling facility to improve quality.

After the end of the First World War and nationalization in 1919, the Beočin plant continues to expand. The financial crisis in the country in 1925 influences cement production as well, but already in 1926 Beočin introduces a “special cement” that receives high recognition. The plant is further modernized in 1930, with the construction of a clinker hall and a large milling facility to improve quality.

Just before the outset of the Second World War, the Popovac plant produced 44.000 tons of cement a year and the occupation authorities maintained production during the war period. During the war, some of the vital production capacities and installations at Beočin were mined, resulting in the absence of energy in the plant, which was therefore obliged to cease production.

The second half of the twentieth century

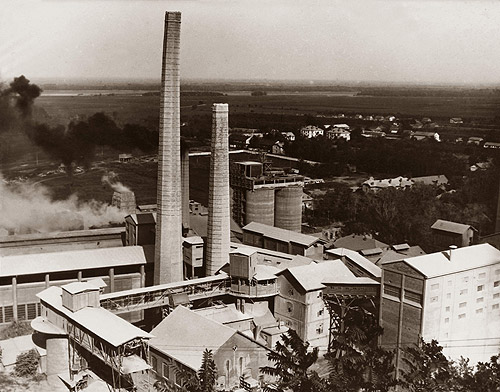

The end of the Second World War saw the establishment of a new social order. The Popovac plant was nationalized in 1946. The new factory was finished in 1956, which received, as a reflection of the new times, the name “Novi (“New”) Popovac”. At the start of the Sixties, annual production is almost 300.000 tons a year. The plant is linked to the main railway line with a normal-gauge spur and a paved road connecting it to Paraćin and the Belgrade-Nis highway allows for improved communication. The passage to electricity as energy in the Old facility, the dry method in the New facility and the introduction of fuel oil lead to the increase in production of 400.000 tons per year.

The post-war reconstruction of the Beočin plant was concluded rapidly and already in 1947 production levels are at pre-war levels. During the Sixties of the last century, Beočin brought on line the first rotational kiln with a 500 ton capacity purchased in Copenhagen, while in 1967 a canal of a length of 1.500 meters was dug linking the plant to the Danube in order to facilitate transportation and communications. Between 1968 and 1970 a second rotational kiln is installed, leading to an annual production level of 1 million tons. The Seventies bring to Beočin another significant change: introduction of production of cement plaster named “Beomal”, the result of the plants own research. As an answer to the demand posed by growth of the market, a new production line with a capacity of 3.000 tons of clinker per day and using the dry method is installed.

A new plant, at a third location is established as the result of exploration of the raw materials base. Detailed investigations and explorations, primarily in the area of non-ferrous metals, confirmed the existence of substantial reserves of limestone, marl and clay, basic ingredients for cement production and in quantities that would allow for economic exploitation and production over an extended period in the vicinity of Kosjerić. The Kosjerić Municipal Assembly and the “Kirilo Savic” Research Institute, as the manager of the design project, decided jointly in 1970 to locate the new plant in the immediate vicinity of Kosjerić. The construction site was inaugurated on 25 September 1971, production starting in 1976 with an annual capacity of 250.000 tons at the outset, increasing to 400.000 tons a year already during the Eighties.

At the end of the Seventies, the Popovac plant receives completely new technology and a rotational kiln with a capacity of 1.000 tons of clinker a day. The result was that annual output was increased to 700.000 tons of cement. Another kiln with a capacity of 2.000 tons of clinker per day was installed in 1981, leading all together to an annual production level of over 1 million tons.

Sources: “Beočinski Dragulj”, 170 years of Lafarge BFC, 2009;Unfinished text “Paraćin Municipality”, “Wikipedia”; TCK.

The consequences of the problems at the end of the century – dissolution of the country and state, war and international sanctions – all affected the cement industry as well as the whole of the Serbian economy. It was a time of technological backwardness and extremely adverse business operations conditions.

The 21st century

The new chapter in the history of the Serbian cement industry starts in 2002, the year when all three plants gained new owners : world known and renowned companies.

The Beočin plant was purchased by the French company Lafarge, the world leader in production of construction materials, together with two Austrian partners, Asamer and Wietersdorfer, as minority shareholders. Over a period of 8 years the shareholders invested 102 million Euros, the purpose of these investments being modernization of the plant, increase in production capacity, improvements in the field of environmental protection and optimization of use of energy.

The owner of the cement plant in Popovac became Holcim Auslandbetailungs GmbH, who invested from the moment of acquisition of ownership of the plant more than 100 million Euros. Among the investments one should particularly note significant improvements in the infrastructure of the plant, improvement of the technology of the production process, environmental protection, enhancement of the usage of alternative fuels as well as programs of support for the local community where the plant is located.

The Kosjerić cement plant became part of Titan Cement Company SA, a noted Greek and international cement producer. Since privatization, over 50 million Euros were invested in improvement of environmental protection, safety at work, increase in production capacities and optimization of the production process.

Today, operating within the framework of renowned international cement producers, the plants at Beočin, Popovac and Kosjerić continue their development and improve their technologies, adjusting themselves to the requirements of contemporary principles of sustainable development.