About cement

History of portland cement

Invention of hydraulic binders

During the second half of the XVII century, John Smeaton, an English engineer, invents hydraulic limestone. During his experiments, Smeaton came to the conclusion that by baking one mineral raw material (limestone with some premises of clay) it is possible to obtain a binder of very good qualities. However, a broader implementation of this procedure starts with the invention of a new hydraulic binder, for whose devising the credit belongs to Joseph Parker, also an Englishman. Due to its similarities to the color of the plaster that was made by builders on Ancient Rome, this new kind of hydraulic binder, obtain through the baking of one kind of marly limestone was initially called “Roman cement”. With the devising of “Roman cement” the industrial production of hydraulic binders genuinely starts.

Progress in development of hydraulic binders is also marked by the almost simultaneous invention of a new procedure for production of hydraulic limestone articulated by J. Frost in England (1822) and Vicat in France (1835), by which hydraulic binder can be obtained by baking a mixture of limestone and clay previously grinded through a wet procedure. This kind of binder, commonly referred to as “British cement” , may be considered as a predecessor of industrial production of cement binders, due to the fact that it set down the basic principles on which even contemporary production of cement is based.

Natural cement

The next stage in the development of production of hydraulic binders represents the invention of natural cement. In 1850 David Saylor came to the conclusion that baking natural marl from a quarry in Pennsylvania can result in the obtaining of excellent binder. The same year marks the establishment of the first industrial plant for production of so-called “natural cement”, whose qualities locate it somewhere between hydraulic limestone and genuine Portland cement.

Predecessors of Portland cement

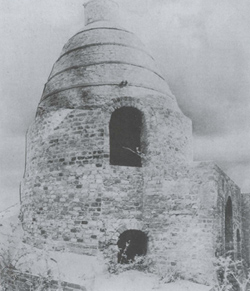

Even though the discovery of real Portland cement is attributed to Joseph Aspdean and his contribution is beyond dispute, cement was through his procedure baked at a temperature below sintering (process of heating of powder materials at the temperature directly below of it melting point to form a new material with very uniformed content) and did not differ significantly from Parker’s “Roman cement” and Frost’s “British cement”. For the production of his cement Aspdean started with limestone superficially extracted, grinded and calcined it, the resulting lime mixed with clay and baked the resulting mass in kilns for production of lime, milling again the resulting product into fine texture. Due to the significant similarity to the color of hardened plaster and concrete obtained from rock in the English province of Portland, this product was named “Portland cement”. However, this initial “Portland cement” was not baked at the temperature of sintering, even though Aspdean should be credited for first coming to the idea that through the baking of a mixture of limestone and clay hydraulic binder can be obtained.

“Real” Portland cement

Somehow during the same time, Isaac Charles Johnston, also an Englishman, note that balls of baked material give binder of an even higher quality and thereby discovered that the solution for the production of “real cement” lies in baking at very high temperatures of a mixture of limestone and clay in a proper proportion. Through increase of the baking temperature to the temperature of sintering and by the use of a mixture in a precisely designated relationship of limestone and clay, the industrial manufacturing of Portland cement began, while 1844 is considered as the “year of birth” of real Portland cement.

Source: “Manual for the production and application of the non-metallic construction materials”, Book 1, Predrag Brzakovic, Belgrade, 2000